- Support portal

- Evaluation Kits and partner products

u-blox Support

- Product documentation

Documentation

- Investor relations

Investor relations

Predictive maintenance, also known as remote or condition monitoring, has existed for several decades. Predictive maintenance best practices can be traced back to the aviation and military sectors in the 1940s and 1950s. Back then, monitoring systems could detect and predict potential failures in aircraft engines.

During the second half of the 20th century, the idea of predictive maintenance gained attention in the industrial sector. With the advent of computers and the increasing availability of sensors, industries began to explore ways to make use of the available data to predict equipment failure and optimize the performance of machinery and equipment by scheduling appropriate maintenance.

In the 1990s and 2000s, predictive maintenance became a familiar term across various industries. More specific predictive maintenance technologies and techniques emerged. The Internet of Things (IoT) and increased connectivity of industrial equipment brought more sophisticated solutions. During these decades, predictive maintenance solutions began to use real-time data, machine learning, and predictive analytics.

Predictive maintenance is a well-established practice in industries as diverse as manufacturing, energy, and transportation. It uses sensor data, historical maintenance records, bid data, and other relevant information to predict potential equipment failures.

By leveraging machine learning, data analytics, and modeling, predictive maintenance anticipates potential issues, schedules maintenance tasks more efficiently, and reduces the likelihood of unplanned downtime and costly repairs.

Predictive maintenance solutions effectively detect changes in equipment performance and condition by relying on on-time information. This approach provides access to the status of individual assets, processes, or even entire smart factories.

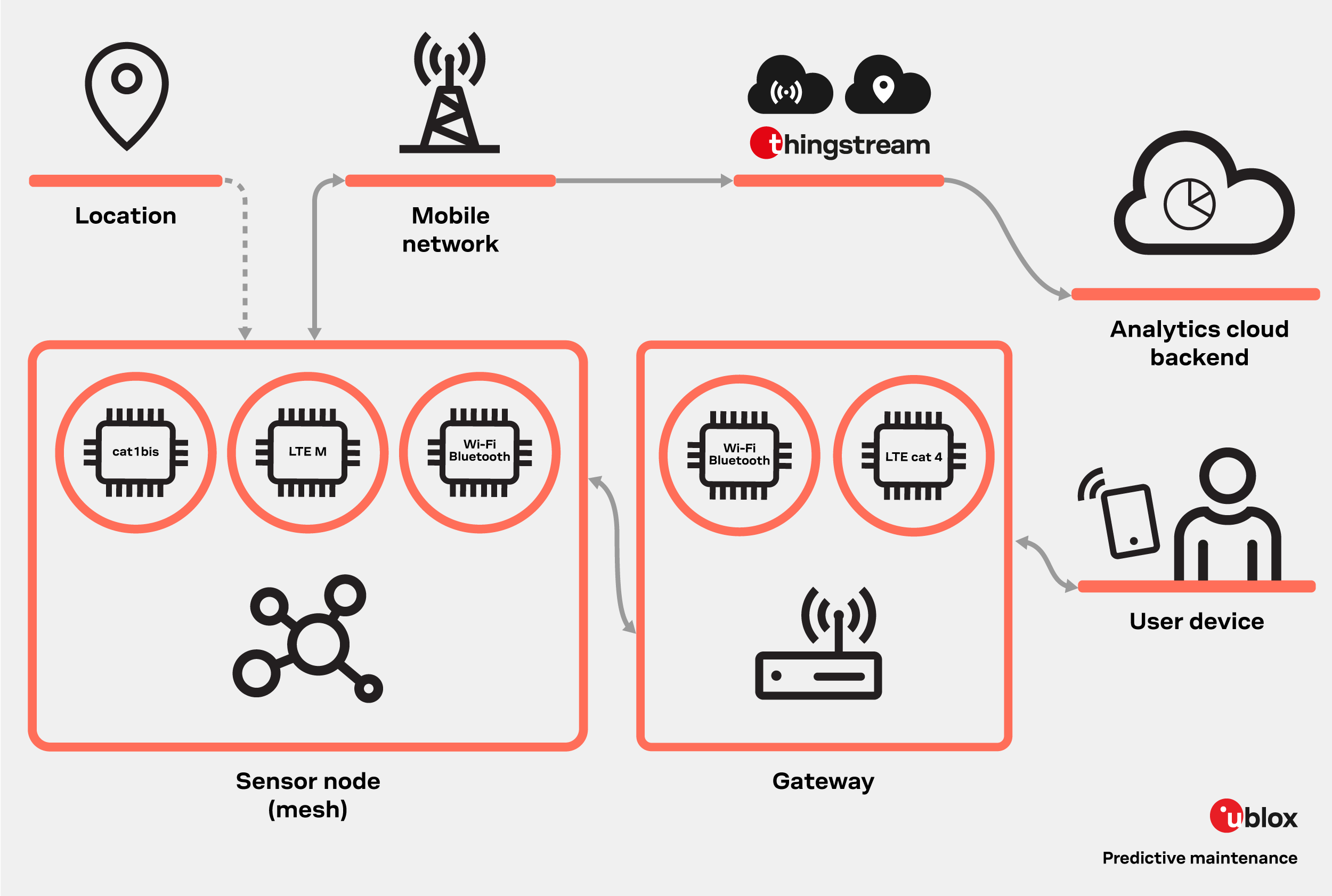

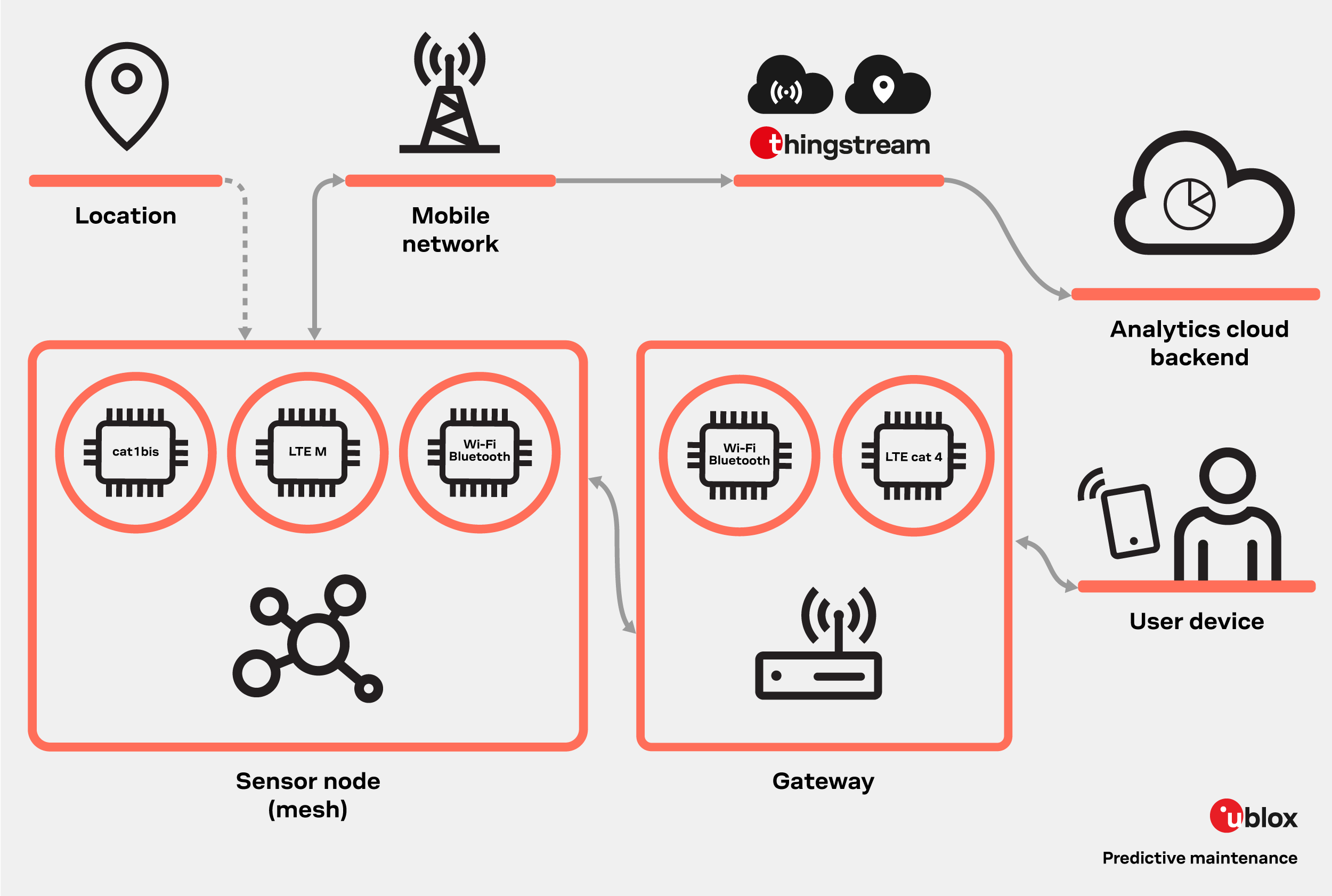

Many predictive maintenance solutions can be implemented in the field. They involve data analysis at various levels. The following are some critical areas within the domain of predictive maintenance.

Machine learning and data analytics. Predictive maintenance utilizes data analytics and machine learning algorithms to process sensor data, identifying patterns, anomalies, and trends that indicate potential equipment failure.

Sensor nodes. Sensor nodes collect critical predictive maintenance data like temperature, pressure, and vibration. Deployed within machines or operating environments, they provide real-time data for analysis.

Mesh sensor network. A mesh sensor network is a group of interconnected sensor nodes that relay data to a central hub or collection point. This network facilitates the transmission of information across multiple locations.

Condition Monitoring Techniques. Condition monitoring techniques like vibration analysis, thermography, oil analysis, and acoustic emission testing help assess the health of machinery, which is essential to prevent potential equipment failure.

Predictive Maintenance Software Platforms. These platforms offer comprehensive data management and analysis, with features like real-time monitoring, predictive analytics, alerts, and maintenance planning tools.

Predictive maintenance is also a gateway to innovative business models. For example, by offering "availability as a service," companies can transform their business model from simply selling motors to ensuring continuous machine rotation. This strategic shift is not limited to mere transactions but can help create lasting partnerships to improve visibility, optimize maintenance, and ensure sustainable machine availability.

IoT Communication-as-a-Service SIM-based LPWA

MQTT-SN communication with flexible connectivity

Stand-alone Wi-Fi 6 multiradio modules

Stand-alone dual-band Wi-Fi modules with Bluetooth Low Energy

Single or multi-mode LTE Cat 1 modules

Single-mode LTE Cat 1bis modules

LTE-M / NB-IoT / EGPRS module

Contact us and we'll be in touch as soon as possible: