- Support portal

- Evaluation Kits and partner products

u-blox Support

- Product documentation

Documentation

- Investor relations

Investor relations

Connected tools have evolved rapidly over the past few decades. In the early 2000s, tools were equipped with basic connectivity features by integrating sensors that provided basic communication capabilities to transfer data. The mid-2000s brought tools without physical cables, mainly due to the availability of high-energy battery technology.

By the end of the same decade, “smart tools” landed on the scene. The ability to process data internally gave users access to real-time data, including feedback and insights. The Internet of Things (IoT) took connected tools to a higher level, and from the mid-2010s and beyond, cloud connectivity enabled managing data remotely. Some features introduced for these smarter tools were performance tracking, predictive maintenance, and data analytics.

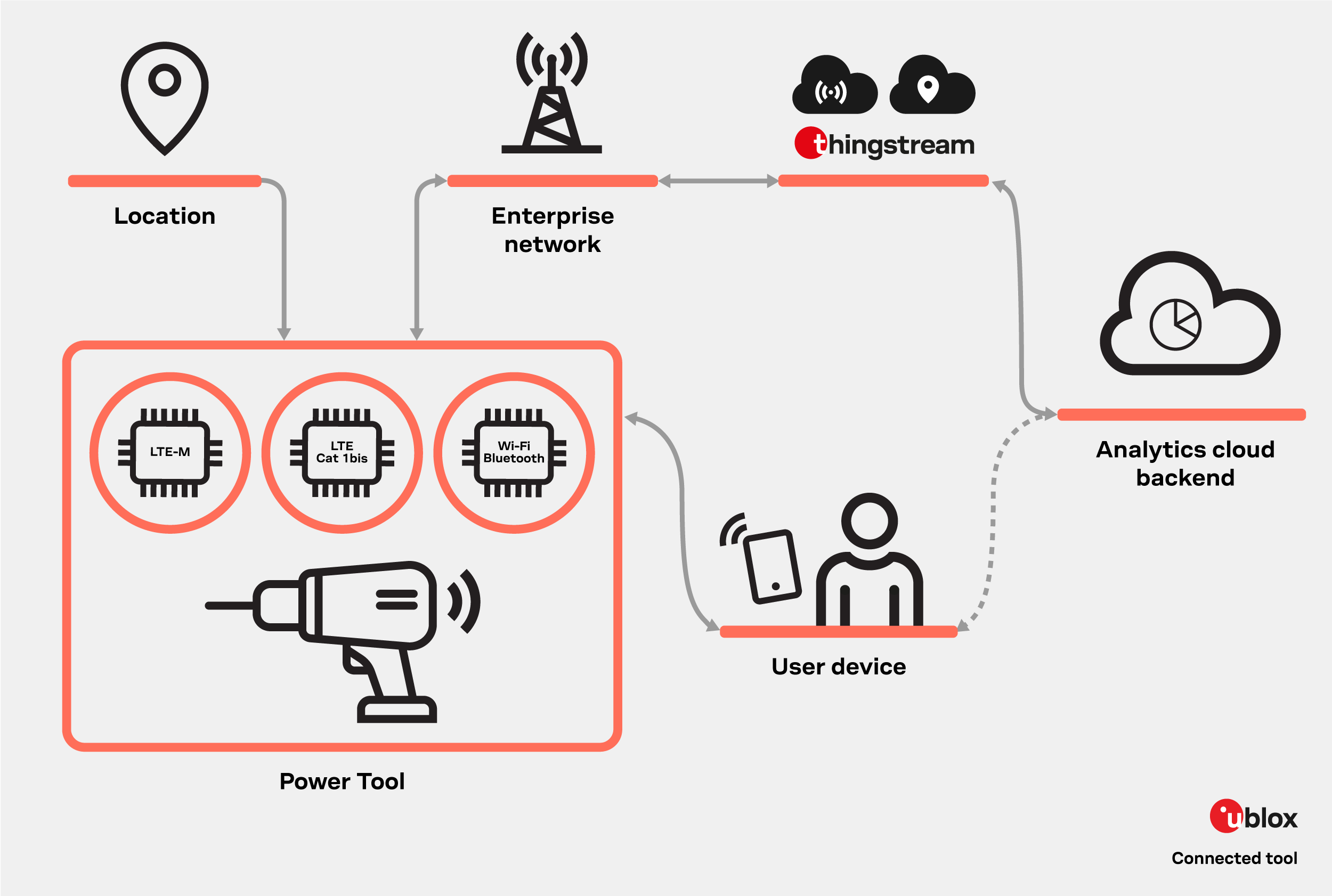

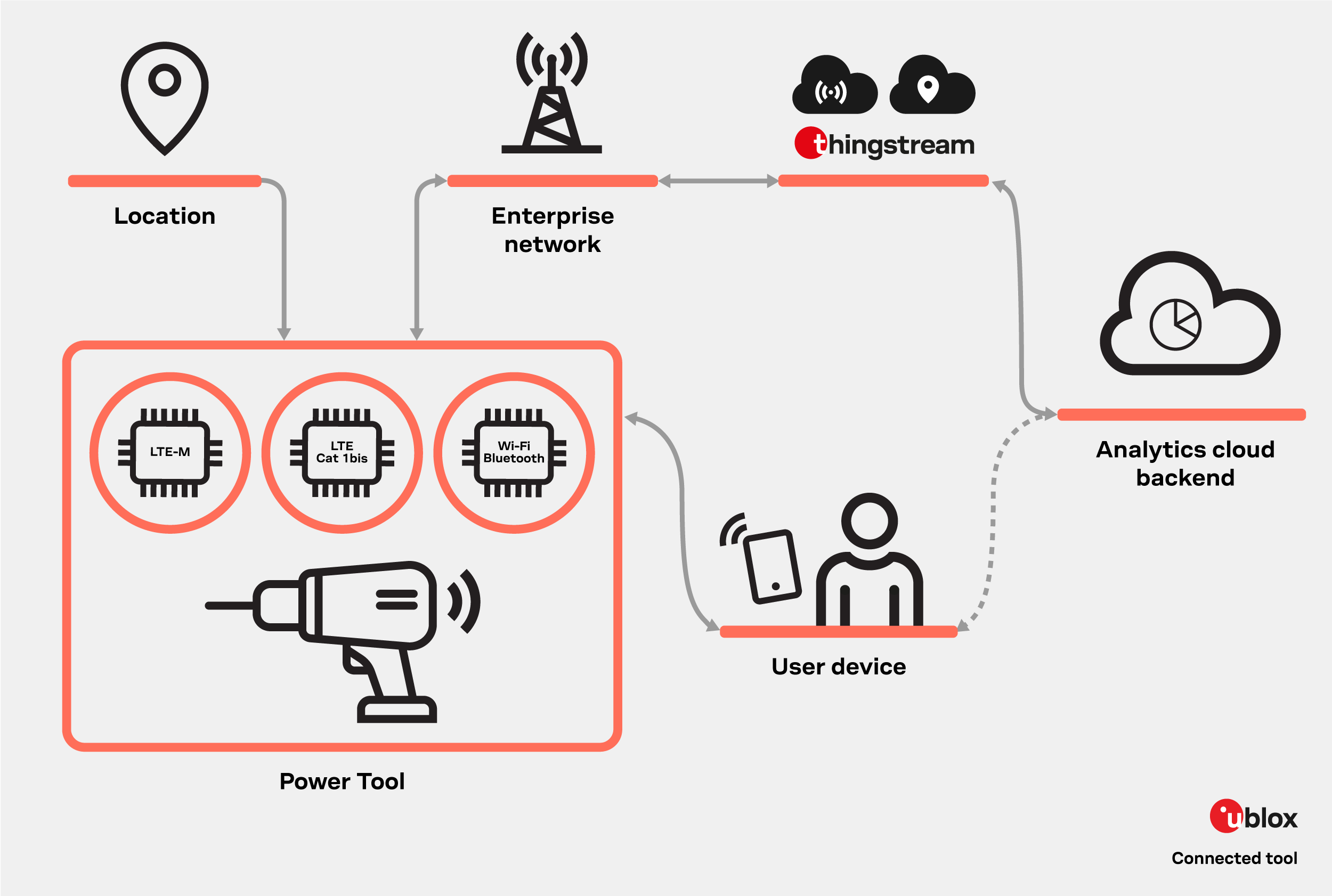

Connected tools encompass devices or instruments equipped with connectivity capabilities. They can communicate or exchange data with other devices, systems, or networks. Smart tools typically establish communication via Wi-Fi, Bluetooth, or other communication protocols. In the IoT world, connected tools carry sensors, software, and connectivity to collect and share data.

Connected tools facilitate personalized settings and integrated usage analytics to improve performance, accuracy, safety, and efficiency. In addition to industrial assembly solutions, these smart tools benefit smart sites, connected manufacturing plants, and construction sites by providing access to critical data harvested from individual workers.

Connected tools enhance the user experience and facilitate the monitoring and tracking of these smart tools, preventing theft and loss within a smart site. Moreover, personalized user settings can address the specific needs and preferences of individual workers.

Connected construction sites and factories or warehouses are places where smart tools have been integrated into daily activities, swiftly replacing traditional hand tools. With increased durability, performance, precision, and operational efficiency, these smart tools make processes more efficient and improve production in a connected factory or construction site.

Connected tools and industrial assembly solutions directly impact the bottom line as they:

Today, a connected tool should offer two main features: reliable localization and seamless connectivity. To achieve this, the connected tool must be equipped with an essential component: a dependable cellular or short-range module.

Cellular modules for connected tools, primarily used in industrial automation, thus require integrated positioning, bundled connectivity, extended low-power battery life, and an integrated eSIM. u-blox’s extensive portfolio offers the most densely packed modules with these features.

u-blox’s short-range modules are optimized and best suited for indoor positioning solutions like smart factories. They provide indoor location and direction with sub-meter accuracy. They support multiple technologies and enable easy migration to new generations based on a well-established form factor roadmap.

At u-blox, our catalog includes a wide range of modules, each designed for specific needs and scenarios.

Stand-alone Wi-Fi 6 multiradio modules

Stand-alone dual-band Wi-Fi modules with Bluetooth Low Energy

Host-based Wi-Fi 6/6E and Bluetooth 5.4 modules for the IoT

Stand-alone Bluetooth 5.2 low energy modules

Single-mode LTE Cat 1bis modules

LTE-M / NB-IoT / EGPRS module

IoT Communication-as-a-Service SIM-based LPWA

Positioning in the cloud

Contact us and we'll be in touch as soon as possible: