MAX-M10 series

u-blox M10 standard precision GNSS modules

Insights

|

18 Jun 2021

Track your assets in real-time with IoT supply chain monitoring for increased revenue, efficiency, fraud and tampering detection, and peace of mind.

In many industries, supply chains continue to be remarkably opaque. At their best, they run like perfectly orchestrated systems, the result of decades of process optimization. Still, much can happen to raw materials and finished goods as they transit to and from manufacturing sites. They can get damaged, degraded, accidentally mixed up, deliberately exchanged, lost, stolen, or simply delayed, each of these events requiring immediate remediation to avoid further delays. With the prevalence of just-in-time manufacturing and the subsequent reduction of storage capacities, early deliveries can be as disruptive as late ones.

The Internet of Things is bringing a new degree of visibility and predictability to all stages of the supply chain, combining extensive sensing, satellite-based positioning, wireless communication, and cloud platforms for data storage, processing, and visualization. To pry open the black box of conventional supply chains and shine light into all their processes, a growing number of industries are adopting IoT supply chain monitoring based on real-time location systems (RTLS) to save time, money, nerves, and in the pharmaceutical and medical sectors, lives.

Assets are at the heart of supply chains – and they are a mixed bag. Transported in bulk, packaged into bags or boxes, stacked onto pallets, loaded into cargo containers or unit load devices used in aviation, these assets traverse oceans, continents, factory floors, warehouses, and retail locations on the way to their next, sometimes final, destination. Vaccines and fresh fish may require varying degrees of cooling, fragile assets many need careful handling, and “attractive” products heightened levels of security against tampering, corrupt misappropriation, and theft.

This diversity in terms of packaging, transportation, and monitoring needs calls for versatile asset tracking solutions capable of locating the assets across a range of environments, indoors, outdoors, on rail, road, and sea. They need to be able to upload location and, potentially, monitoring data to the cloud. And, because of the global nature of today’s supply chains, they need work everywhere on the planet.

Regardless of where they are deployed, IoT asset trackers are made up of a common set of building blocks and are subject to a common set of requirements. Deciding which positioning solutions, wireless communication technologies, and services are the best match for a given use case requires carefully weighing competing interests in terms of edge versus cloud computing performance, geographical coverage, technical features, end device size, and cost.

In an ongoing series of blogs, we will explore three broad categories of asset tracking applications and investigate strategies to optimally balance cost, size, and performance for each specific use case.

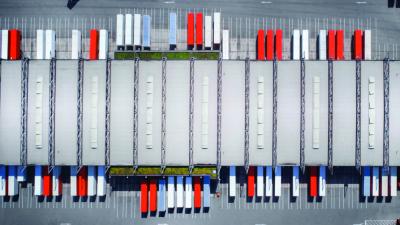

In our first blog, we focused on solutions designed primarily to track the geographical location of large assets – intermodal containers transported across oceans on cargo ships or across continents on semi-trucks, as well as ULDs using in aerial logistics.

The second blog will explore solutions for a growing number of smaller assets requiring sensor-based monitoring in addition to geographical tracking and cloud connectivity.

And the third blog in the series will look at assets at rest, whether in outdoor container terminals or in indoor logistic hubs, factory floors, or warehouses.

Be sure to check in regularly for more insights into building IoT supply chain monitoring solutions to upgrade your logistics operations.

Diego Grassi

Senior Manager Application Marketing, Industrial Market Development, u-blox