- Support portal

- Evaluation Kits and partner products

u-blox Support

- Product documentation

Documentation

- Investor relations

Investor relations

IoT-connected coolers for brewers, bottlers, and retail

u-blox removes IoT communications complexity for ‘always on’ connected refrigeration.

Predictive maintenance and proactive beverage replenishment are driving the business case for connected refrigerators, freezers, and dispensing equipment. However, because data can now be collected in a globally-ubiquitous and cost-efficient manner, many new opportunities are being derived from the sensor output from connected equipment.

Read on to find out how the IoT – and u-blox – can support brewers, bottlers, and retailers, helping them reduce costs, increase profitability, and improve visibility in asset management.

Advantages

u-blox has enabled brewers, bottlers, and retailers to implement both proof-of-concept and production implementations with ease and at a fixed predictable low cost.

- Reduction in loss of fridges, kegs and other equipment through real-time location awareness

- Maximized earning potential and improved uptime of equipment through predictive maintenance

- Increased revenue through predictive replenishment

- Less wastage through real-time monitoring of consumption

- Improved product experience through real-time quality control

When developing an IoT strategy to support your business, the communications part is not necessarily the first consideration. However, when putting together the many elements in the design of your overall approach, the availability of communications, and a clear idea of running costs will always be an important part of the outcome required.

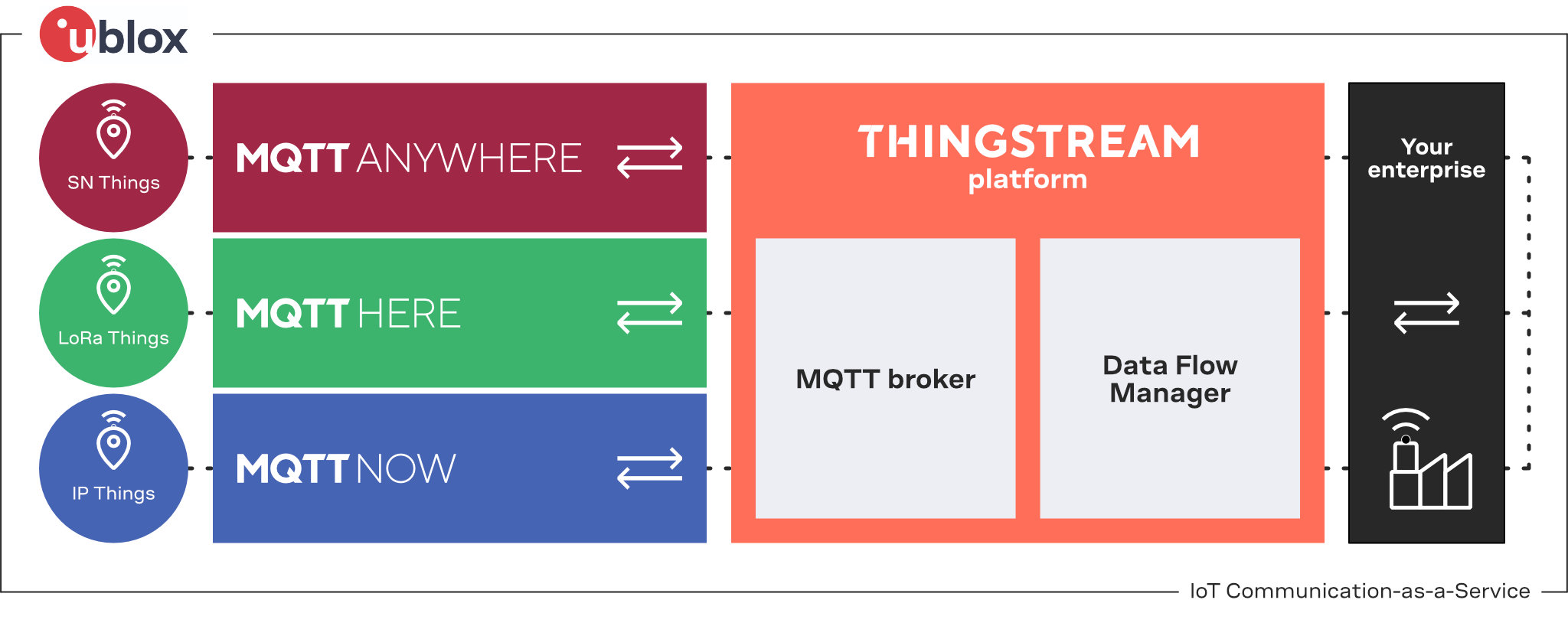

There are many considerations to decide between the design of your device and having unfettered access to the data they create as illustrated below.

u-blox works with brewing equipment manufacturers to enable their equipment to simply transmit their sensor data into the enterprise, for a fixed low price, anywhere on the planet.

Case study - AB InBev